How Does The Sls Camera Work

- What is SLS 3D printing?

- How does SLS printing work?

- What is possible to print with SLS?

- Physical Possibilities of Selective Laser Sintering

- Disadvantages of SLS 3d press

- Hype on Desktop SLS printers

What is SLS 3D press?

Newsmakers tend to show their audience the most exotic objects 3D printed like food, clothes, houses, and other exciting things, essentially blending all 3D press methods together and disregarding the simpler goods which would exist smarter to produce with a 3D printer. When discussing professional person 3D printing, information technology's hard to overestimate Selective Laser Sintering (SLS) technology, which has been on the market since around the mid-1980s. Information technology made quite a splash in the media, bringing to life fancy 3D printed dresses for fashion shows, prosthetics, design furniture and even parts for huge companies like Mercedes-Benz. The technology itself can industry many other things as well thanks to its working principle. Let's take a closer look at SLS engineering.

Image: Formlabs

How does SLS printing piece of work?

Today, there is a whole grouping of 3D printing technologies which use powdered materials to create physical objects past heating the cloth. The key to agreement the specifications of SLS amongst other similar methods is backside these 3 words:

Selective – printer receives a code (educational activity) for each layer of the object(s), which tells information technology where the material should exist selectively solidified to get a 3D structure.

Laser – a high-powered laser to heat powder grains and make them solidify together to class an object, layer past layer.

Sintering – the powder isn't just heated, it's sintered to the point at which grains solidify. Information technology's important to note that since the printer doesn't completely melt the material the parts come out porous.

With no magic involved, SLS printers work through a very uncomplicated procedure. To outset printing, the car requires only 2 things – a file with a code and material used to produce the parts.

- The machine preheats the whole build chamber with powder to the temperature just a little below the sintering betoken;

- Roller creates a sparse flat layer of powder across the platform (working area);

- Laser sinters zones, where object is supposed to exist according to the code;

- Platform descends slightly;

- Printer repeats the key 3 steps again and again until the last layer required has been completed;

- The pulverisation needs to absurd downwards before it can be removed from the machine.

3D print with SLS technology

What is possible to print with SLS?

Depending on a single printer's specifications, SLS machines can deal with diverse materials – starting from nylons and upward to metals and alloys (if units are equipped with strong lasers). SLS technology produces monochrome objects, but as an reward, information technology tin can work with blended powders. The material range is what has probably helped SLS technology to expand its achieve to then many different industries. Here are some of the different materials bachelor for SLS technology:

Nylons – is a broad group of polymers commonly used with SLS printers, with maybe the nearly famous Nylon 12 PA (Polyamide 12). This fabric is considered to be the 1 for "full general" purposes of prints. PA 12 gives a good surface finish, it's thermal resistant and has fine mechanical properties. PA 12 features: white colour, durable, potent, can be flexible, absorbs less moisture, machinable, can be dyed and painted.

TPU – is a thermoplastic polyurethane, which is used to produce flexible parts. Prints announced rubber-like, tin can stand temperatures upward to 80C° and withstand abrasion. TPU features: can be food safe nether certain conditions, can be dyed, appears off-white.

TPA (PEBA) – another flexible thermoplastic with the appearance of rubber. Compared to

TPU, it is more than solid and comes out plain white. It has high elasticity, is chemically resistant, and has long-term stability.

PEEK (Polyether) – the material requires loftier temperatures to exist sintered. Parts made from PEEK pretend to replace metal details due to their stiffness, excellent mechanical properties, and strength-to-weight ratio. PEEK features: is flame retardant, tin can be sterilized, temperature and chemical resistant.

Casting Plastic – this powder is a polystyrene-based material, suitable to replace wax primary patterns for molds used in metal casting. It can work with low melting-temperature metals, burns out presently, and it is like shooting fish in a barrel to procedure.

Metal powders – a range of metallic and blend powders, including steel, aluminum and titanium. After existence sintered, these powders appear similar to metallic and can be used to produce tools, metal parts. Such prints can be machined and polished.

Ceramics and Porcelain – at that place are a agglomeration of powders and pastes, which make it possible to print ceramics or porcelain objects with SLS machine. Depending on the exact proportion, prints can be microwave, dishwasher, and oven safe, strong, and biocompatible.

Image: Creative Tools

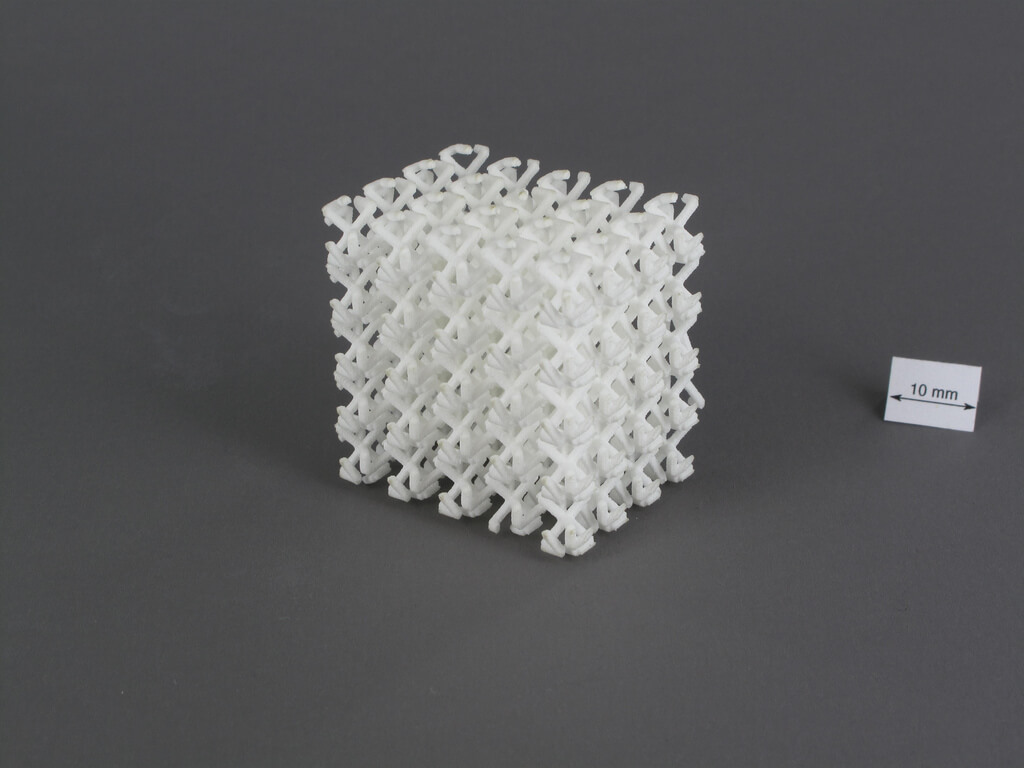

Physical Possibilities of Selective Laser Sintering

Every bit industrial Selective Laser Sintering (SLS) printers are considerably big in stature and equipped with powerful lasers, these machines are capable of impressive printing volumes and can work with tough materials which crave loftier temperatures. The fact that the technology doesn't extrude or polymerize materials means that information technology has a huge blueprint advantage – it doesn't require supports. The actual powder used for printing becomes its own support structure so hangouts and "flight" parts come out quite well.

The laser beam and powder grains are relatively small as well, which ways that some details that are impossible with FDM applied science, for example, are produced with precision. Functional parts and prototypes come out accurately, fit one some other and tin be sent to the market right after being postal service-processed.

During a print, the entire working expanse is filled with powder which creates possibilities for nesting many parts in one go. Compared to FDM printers that are limited past their X and Y parameters, SLS machines are much more effective for active production.

Sintered powder in prints appears porous, and equally a issue, it absorbs moisture like different paints and dyes.

Nearly all SLS press materials can exist machined and endure certain amounts of stress. Their structure is complimentary from layers with grains that are sintered at their very core, so compared to common FDM press, parts appear stronger. Typically, SLS machines require:

- Engraved/embossed details to be at least 0.5mm thick

- Tiny details to be 0.2 mm minimum.

- Hollow objects to take an open up side or every bit they are called "escape holes" – to let the unused powder leave the inner surface area.

- Printing complex objects with mechanical/moving parts, you should keep in mind 0.5 mm clearance.

Epitome: Jared Tarbell

Disadvantages of SLS 3d press

SLS technology and the materials used with it have been going through continuous advancements over time. Notwithstanding, equally is the case with other fabrication and prototyping methods, it has several limitations or disadvantages:

Shrinkage of prints

Nylons and other powdered materials shrink after being sintered in all three dimensions. The charge per unit of shrinkage unremarkably depends on a number of factors including the type of powder used, the power of the laser applied to sinter grains, the geometries of a part and cooling processes. It'south also interesting to notation that a role doesn't necessarily shrink symmetrically in all directions. Usually, software used to piece models and prepare them for the SLS process includes shrinking parameters into calculations to deliver a good quality function. However, an engineer who works with a printer should be enlightened of this disadvantage and predict if it could happen with a particular slice.

Postal service-printing

Unearthing fresh SLS prints closely resembles the work of an archeologist. After the press session is consummate and the pulverization has had enough fourth dimension to cool downward, the block of material (which can counterbalance upwards to several kilograms) is taken out. A specialist then would need to dig parts out of the cake, remove excess pulverisation with a vacuum, brush away leftover grains or even use an air blower. Once all that is done, sintered prints should exist cured by heat to reinforce their strength. Other finishes are optional and may have some time to sand, dye or glaze print.

Color changes/Moisture absorption

Porous structures which can be an advantage if prints would be dyed, painted or coated, can pose a problem if finishes are absent-minded. They tend to absorb quite a lot of dust, oils and moisture from the air which tin lead to the changing of color (from white to ivory, for example) or loss of strength. The demand to fully load the printing bed. An SLS printer doesn't care if you demand to print a tiny function – it would require loading to cover the unabridged peak of a piece, likewise as the need to have the X and Y fully embedded in pulverization at all times. Even if the material doesn't come up into contact with the laser, the entire contents of the load become damaged subsequently every run. That'southward why owners of SLS printers endeavour to load the press area as much every bit possible for a single procedure.

Automobile and material costs

SLS printers cost a lot. The "affordable" desktop versions are priced around $7,000 – and that's simply the printer. If someone plans to process a full bike with cleaning, postal service-processing, finishing, and curing, they're going to need a lot more money. Materials also cost a fortune – a kilogram of PA 12 can be purchased for about $100-120 through some affordable manufacturers, but a car "eats" several kilos in a unmarried run. If you're planning to get industrial grade, be gear up to invest over $800,000 for a high-stop system.

Using some fresh pulverisation every time

Most sintering printers do preheat powder earlier they come up into contact with the laser, so the material becomes damaged due to temperature changes. Some materials can be reused (recycled), however, press with damaged powder won't terminate well – manufacturers recommend mixing it in with unused cloth. Depending on the material and blazon of motorcar, upwards to 85% of pulverization tin exist recycled but there may yet remain several kilograms of non-sintered material that are damaged and useless.

Hype on Desktop SLS printers

Hobbyists tried to replicate SLS machines at habitation with their own custom designs and technical solutions. Some of them were able to produce working printers capable of sintering powder. For example, in 2013, a project called OpenSLS project was started where SLS machines could be congenital for less than $ten,000. Another maker managed to create a printer for but under $500 with a working area of 80x80x80 mm and experimented with mixing their own powders. Other enthusiasts tried printing sugar with DIY SLS machines with relative success.

Image: Andreas Bastian

Until 2014, modernistic SLS printing applied science had been locked under a patent, which meant that mostly industrial machines were available after several manufacturers. Every bit a patent expired, companies began to rapidly develop the technology and some of them aim to bring SLS to the masses by producing low-cost ($7,000 or even $x,000 is affordable compared to $100,000, right?) desktop machines. Power capabilities and precision still need to exist improved to reach the level of some industrial printers, withal, these machines are still capable of producing quality and authentic parts. These campaigns have garnered a lot of attention and in a competitive environment can near definitely push button SLS technology to the forefront.

Comprehend image by ESA

Source: https://www.treatstock.com/guide/article/116-why-every-industy-needs-sls-3d-printing

Posted by: nelsoncovelf.blogspot.com

0 Response to "How Does The Sls Camera Work"

Post a Comment